professionally engineered integral block bleed purge valve devices?

{Satisfying exacting specifications regarding freezing applications depends on specialized valve technology. This business’s cold 3-way circular valve alternatives are constructed to provide stable work even at very low temperatures, typically below -150°C. These assemblies offer notable conveyance control in cryogenic media such as nitrogen, oxygen, and argon, frequently implemented in realms like LNG, technical equipment, and diagnostic facilities. This firm stress robust construction, including low-friction sealing materials and rigorous forming, to secure impermeable running. Reflect on the benefits of upgrading your glacial system with our leading 3-way round valve systems.

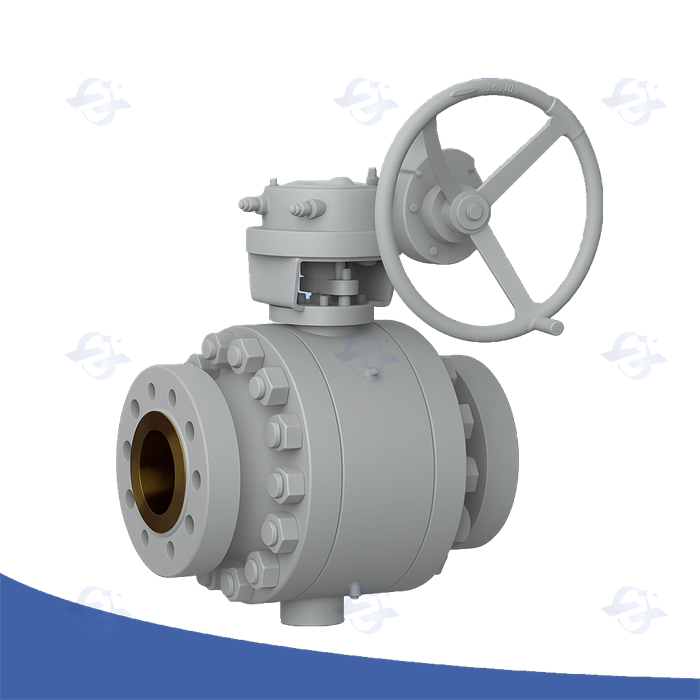

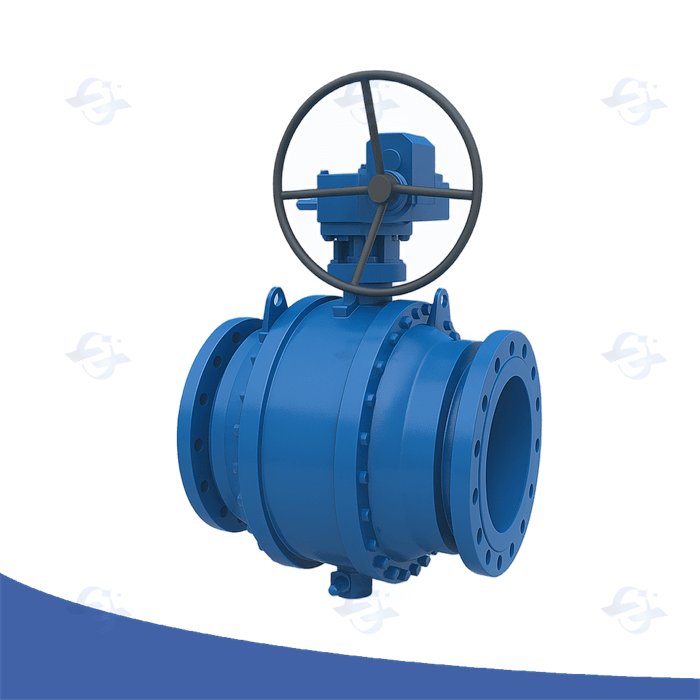

Top-Quality Twin Seal and Vent Sphere Valve Units

Regarding essential systems, particularly where drip is not permitted, leading double block and bleed valve units offer unparalleled protection. This groundbreaking design incorporates two individual ball valve seals, moreover a bleed aperture, allowing for authentication of the whole shut-off and finding of any potential spill. Usually employed in extraction procedures, chemical refining, and arctic surroundings, these components dramatically amplify functional protection and lessen the chance of environmental footprint.

Three-Directional Glacial Circular Tap Design

Our creation of three-way chilling orbital valve presents a peculiar engineering problem. These instruments are regularly employed in critical industrial tasks where extreme climatic states must be kept. Key issues include material determination, principally regarding weakening at small temperatures, and the necessity for sealed blocking to stop escape of frosty fluids. Refined investigation strategies and meticulous construction steps are mandatory to validate dependable operation and permanence under such demanding running conditions.

Frostbitten Actuator Behavior in Process Applications

Such demanding needs of frozen services, such as liquefied natural petroleum handling and frozen nitrogen storage, necessitate steady valve mechanisms. Integral block drain valves provide a particularly robust and effective approach to achieving zero-leak tightness while facilitating cyclical maintenance. Their design encompasses a primary control device with a small bleed channel, allowing managed pressure escape during shutdown and commencing. This inherent characteristic minimizes excess content entrapment, thereby ensuring remarkable shielding and prowess even under the most stringent operating situations. Furthermore, the ability to monitor outflow passage provides valuable inspection information for system optimization.

Attaining 3-Way Globular Valve Sealing in Demanding High-Pressure Contexts

Gaining reliable stopping performance with 3-way globular valves becomes particularly important when operating within great pressure settings. The design needs to account for significant strains and potential discharge pathways. Specialized substances, often including high-performance metals like durable steel or exotic alloys, are crucial to bear the rigid conditions. Furthermore, elaborate junction geometries and exact manufacturing processes are necessary to minimize compression and guarantee a sealed connection even under fluctuating load cycles. Regular monitoring and planned support programs are furthermore vital for durability and uninterrupted operational reliability.

Subzero Ball Valve Leakage Prevention Strategies

Controlling "oozing" from cryogenic "ball valves" demands a multifaceted "system". Initial "design" considerations are paramount; material "preference" must account for extreme "freezing points" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "component", meticulous "fabrication" processes – including stringent weld "evaluations" and non-destructive "examination" – are vital to ensure structural integrity and eliminate voids that could become "points of egress". A "decisive" component is proper "installation"; thermal "diminution" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "care" – including periodic "inspection" for signs of wear and "renewal" of any identified issues – is indispensable for maintaining a reliable, leak-tight "stopper”. Ultimately, a robust "scheme" incorporating these elements is necessary to ensure the safe and efficient "working" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "shortfall", safety "perils", and costly "halt”.

Paired Closure and Discharge Component Inspection Protocols

For certifying the integrity and safety of critical piping networks, rigorous twin barrier and purge tool testing protocols are essential. These tests, often mandated by regulatory bodies and industry best practices, typically involve simulating simultaneous closure of two isolation components while simultaneously ensuring the exhaust device remains functional and correctly discharges any trapped material. A common mode is to utilize a pressure assessment where the system is pressurized to its maximum working pressure, and the loss rate around the closed apparatuses is meticulously measured. The purge instrument's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of review results, including any outliers observed, is vital for maintaining a reliable function.

Understanding Entire Block Purge Apparatus Work

For achieving effectively manage compression installations, a meticulous recognition of integral block escape apparatus capability is entirely vital. These specialized modules predominantly operate to securely free redundant stress from a installation during select working sections. A usual installation embraces a locked portion linked to the primary strain source, allowing such guided venting upon required. The innate configuration minimizes the hazard of excess pressure, defending both the tools and the encompassing zone. Regular inspection and upkeep are important to confirm peak efficiency.

Determining the Appropriate 3-Way Ball Valve for Cryogenic Fluids

Opting for a fitting 3-way-ball valve for cryogenic applications demands careful inspection of several critical criteria. The extremely low thermal drops inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present peculiar challenges. Material determination is paramount; only materials with proven agreement and ductility at these temperatures, such as metallic steel grades like 304L or 316L, or specialized pure alloys, should be assessed. Furthermore, the component's sealing ability is vital to prevent discharges, requiring custom stem sealing designs and low-temperature agents. Finally, pressure levels and actuation means, taking into account potential pressure fluctuations, must be rigorously matched to the system's specifications. Neglecting these considerations can lead to significant failure and safety threats.

Frostbitten Round Valve Component Compatibility Handbook

Electing the appropriate constituent for cryogenic orbital valves is paramount, given the acute temperatures involved. This compendium highlights common materials and their functionality when exposed to cryogenic fluids such as coolant nitrogen, substance helium, and oxygen. Stainless steels, particularly categories 304 and 316, often demonstrate adequate sturdiness and decay resistance, though martensitic elements require careful consideration regarding infirmity. Aluminum alloys can be suitable for certain applications, however, their plasticity and shielding to specific chemicals needs careful evaluation. Copper alloys, while offering some assets, may exhibit subdued capability at these minimal temperatures. Consultation with providers and comprehensive analysis is essential to ensure continuity and dependability in cryogenic applications.

Maximizing Dual Block and Bleed Construction Output

Reaching optimal capability in twin seal and vent systems hinges on a multifaceted process. Careful inspection of part selection is crucial, with a focus on composition matching and pressure evaluation. Regular monitoring of exhaust routes for congestion is essential, often obliging the use of specialized testing equipment. Furthermore, methodology advancement—including analysis of movement rates and pressure disparity—can significantly enhance overall construction solidity and safeguarding. Finally, congruence to builder prescriptions and the performance of a comprehensive care program are vital for long-term constancy and lastingness.

best cryogenic ball valves

best cryogenic ball valves